Specialk3700 wrote: ↑Sat Aug 17, 2019 6:09 pm

Very interesting. As someone who has never used ergobone what would be the advantage of this design?

1) The first problem is attaching and reattaching the device. Currently you have to use a big honking steel nut to attach/unattach. That's inconvenient and I almost always drop the nut when I take it off, and it can hit your bell or slide if you're not careful.

2) The second is that the device only pivots in one direction, and if you have to tilt your horn side to side, you have to go against the clamp, which can scrape up your horn.

3) When you take the horn off of the harness if you use that, and put it on a trombone stand, the solid steel rod hangs down next to your slide, which looks bad plus it's just an accident waiting to happen.

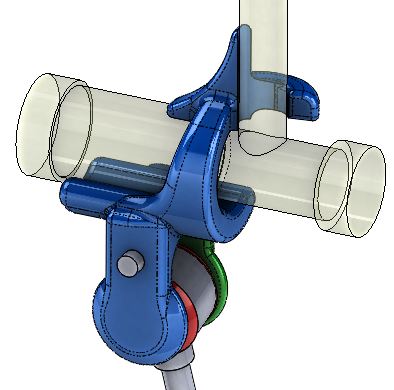

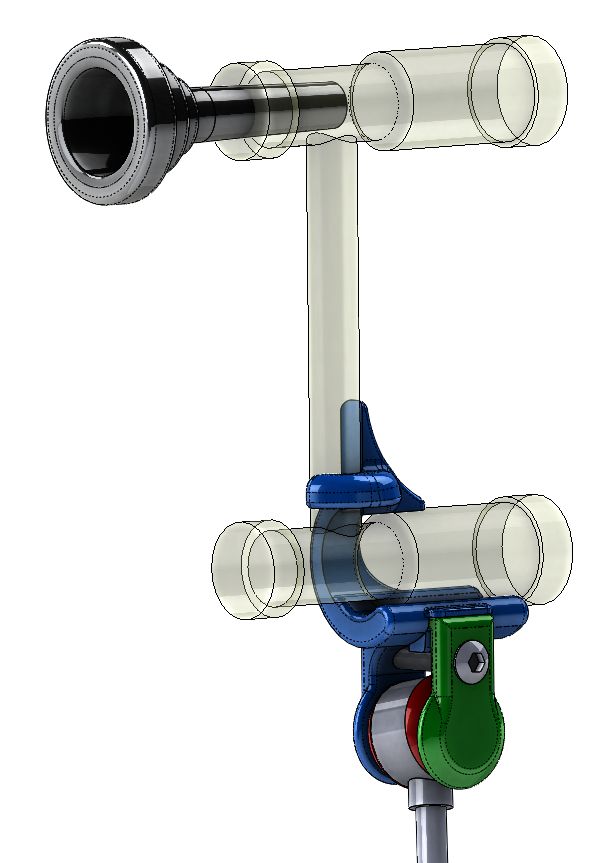

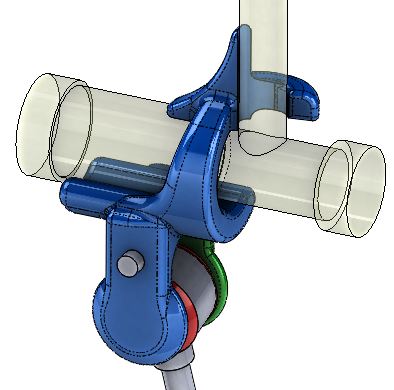

This design enables you to connect to the horn without screws, and the mechanism always remains assembled.

It also makes the pivot into a spherical joint, so you can adjust in any direction.

When you put the horn on the stand, you can remove the device from the horn easily, PLUS,. you can take this design one step further, and replace the steel rod and pivot with a plastic sphere and a hollow aluminum tube. This makes everything lighter, and you don't have that heavy solid steel rod threatening your slide any more. At this point, you've essentially replaced all the parts of the original ergobone.

I do like the spring and the adjustable collar that aren't pictured. I also like the extendable pole.

Below is a second view of the attachment to the lower cork barrel and brace. The nut connecting the bell and slide is on the right, just for reference.

These parts can be 3D printed. I used my Kanstul 1662i for the reference dimensions. Might require a couple winds of electrical tape to make this design fit your horn. If you want the data to 3D print your own, just let me know.